Free Shipping Australia Wide

Made with under the sun daily.

Free Shipping Australia Wide

Made with under the sun daily.

In this short article, we thought to share with you a little about the fresh spirulina manufacturing process, present and upcoming…

Here you can see fresh spirulina right after harvesting, (i.e. taken out of the water/growth media), still vibrating under the sun.

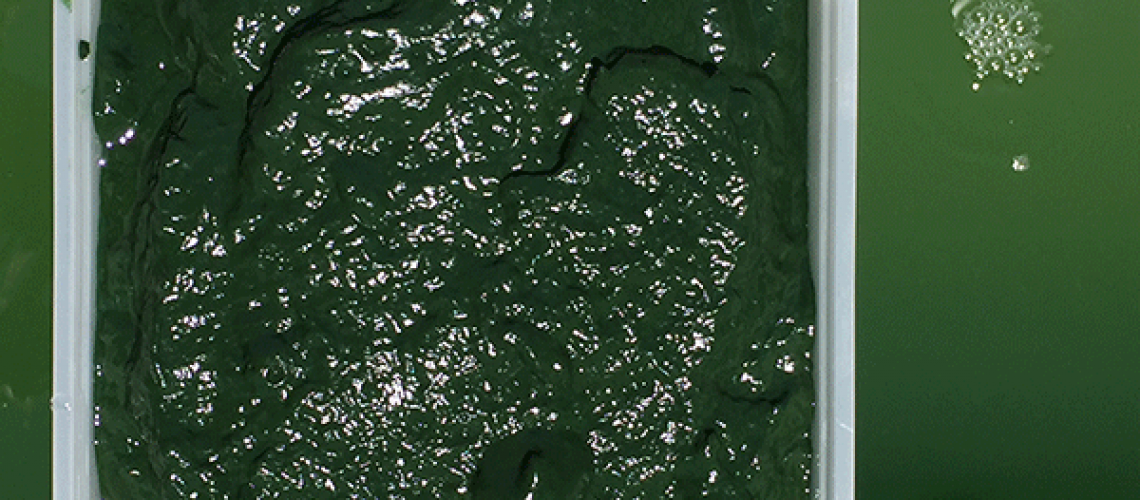

This picture shows the spirulina paste. This is what fresh raw spirulina looks like when the excess water was extracted from it.

This picture featuring freshly frozen spirulina packaged in 20gr portion. Freezing is done immediately after the water extraction to ensure sealing of all the best fresh spirulina has to offer.

This picture is of dried spirulina. These are spirulina flakes, crunch. They go really well in salads and yoghurts, for example, boosting your health by adding minerals, vitamins and plant source protein.

Dried spirulina is not as great as the freshly frozen, though, the dehydrating, heating process is destroying some of its vital health components.

This picture below is of extracted Phycocyanin off the spirulina. We isolated this pigment to illustrate the abundance presence of this healthy pigment in the spirulina. Phycocyanin is the blue pigment that gives the spirulina its blue-green colour. It is a potent and very powerful antioxidant. (e.g. 20 times more potent than vitamin C).

Below the phycocyanin photo, there is another image illustrating what antioxidants do.

You can read about phycocyanin in more details in this short article: Phycocyanin: valuable component of spirulina

The photo above: Illustration of the what antioxidant and free radical are and how they interact. Many people are raising an eyebrow, nod and move uncomfortably when antioxidants are mentioned. On the next newsletter, we will elaborate on those.

That’s about it,

a short tour of how fresh spirulina is manufactured, showing you the beginning and the end results. Other middle stages involve water testing, measuring values (e.g. pH, temp etc..), scanning for properties (e.g. the presence of minerals, vitamins, Omega – 3, 6 & 9 compounds, protein etc..), correct nutrient mixing, quality testing etc…

You are welcome to contact us with questions either through our Facebook page or the contact us form.

Founded in Southeast QLD and located on Certified Organic farmland, we are an Australian-made Fresh Spirulina commercial farm. We are subject to the Australia New Zealand Food Standards Code and produce fresh Spirulina using food-grade nutrients only, pay attention to the freshness and health of our spirulina.

You can visit us at our social media pages at facebook.com & instagram.com

Founded in Australia, Southeast QLD, Fresh Spirulina is a local biotech health company conducting research and innovation of micro & macroalgae as plant-based food products.

By appointment only

Monday - Friday: 08:00am - 16:30pm

Saturday - Sunday: Closed

'Let's Encrypt' SSL certificate installed on this website

*Disclaimer: Spirulina is Food, not drugs or medicine. Statements made, or products sold through this website, have not been evaluated by the Therapeutic Goods Administration (TGA) Australia. They are not intended to diagnose, treat, cure or prevent any disease. Read More »

All rights reserve © 2023, Fresh Spirulina Australia

4 thoughts on “Fresh spirulina manufacturing process”

Awesome post! I read your site fairly often and you always post really great stuff.

I shared this on Facebook and my followers really enjoyed it.

Keep up the good work! 🙂

Wonderful site. Lots of useful information here. I am sending it to some friends ans also sharing in delicious. And obviously, thanks for your effort!

What of this new drying process in the uk that avoids the hot air blast and results in a dry flake or ‘noodle’ that does not have the fishy flavor of typical dried powders? I am trying to find a US source of such spirulina.

Hello Jason,

I am not familiar with that new process you are talking about. We make flakes as well in a controlled environment and still, as time goes by the flakes too, have that familiar Spirulina smell. Only fresh Spirulina doesn’t smell.

Think of it when it comes to fish. Fresh fish of the sea don’t smell, you hold them out for a little while and even though they are still good for consuming they develop that bad smell.

Comments are closed.